Our Solutions

Systematic breakdown of complex tasks into manageable sub-projects – including requirements and solution matrices for sound decision-making.

Development of customized fixtures, tools, and equipment precisely tailored to the customer’s production requirements – including mechanical and mechatronic solutions.

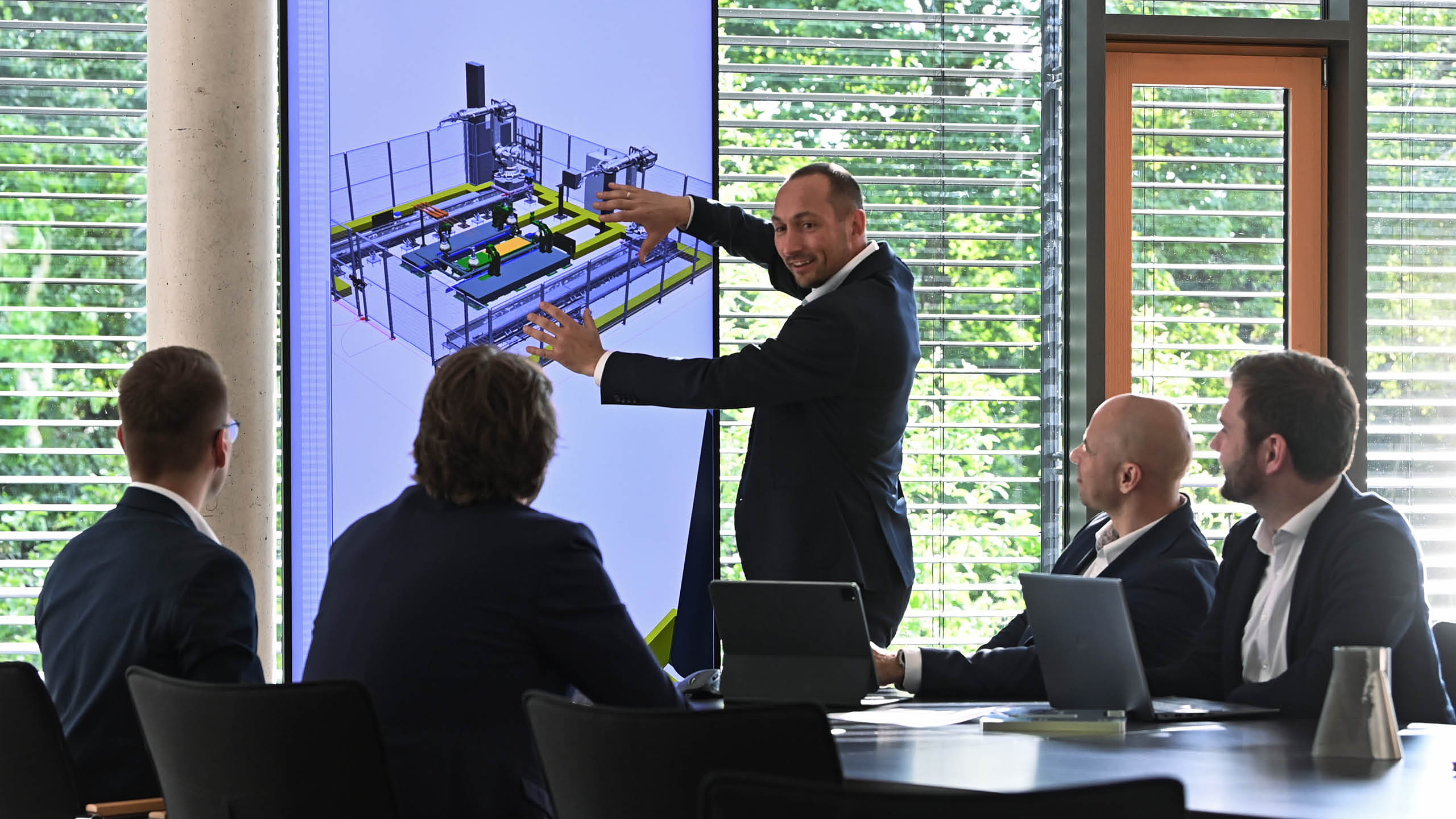

Execution of simulations and virtual commissioning to minimize risks and shorten project timelines.

Precise capture and modeling of production environments using laser scans, complemented by continuous data maintenance and digital twins.

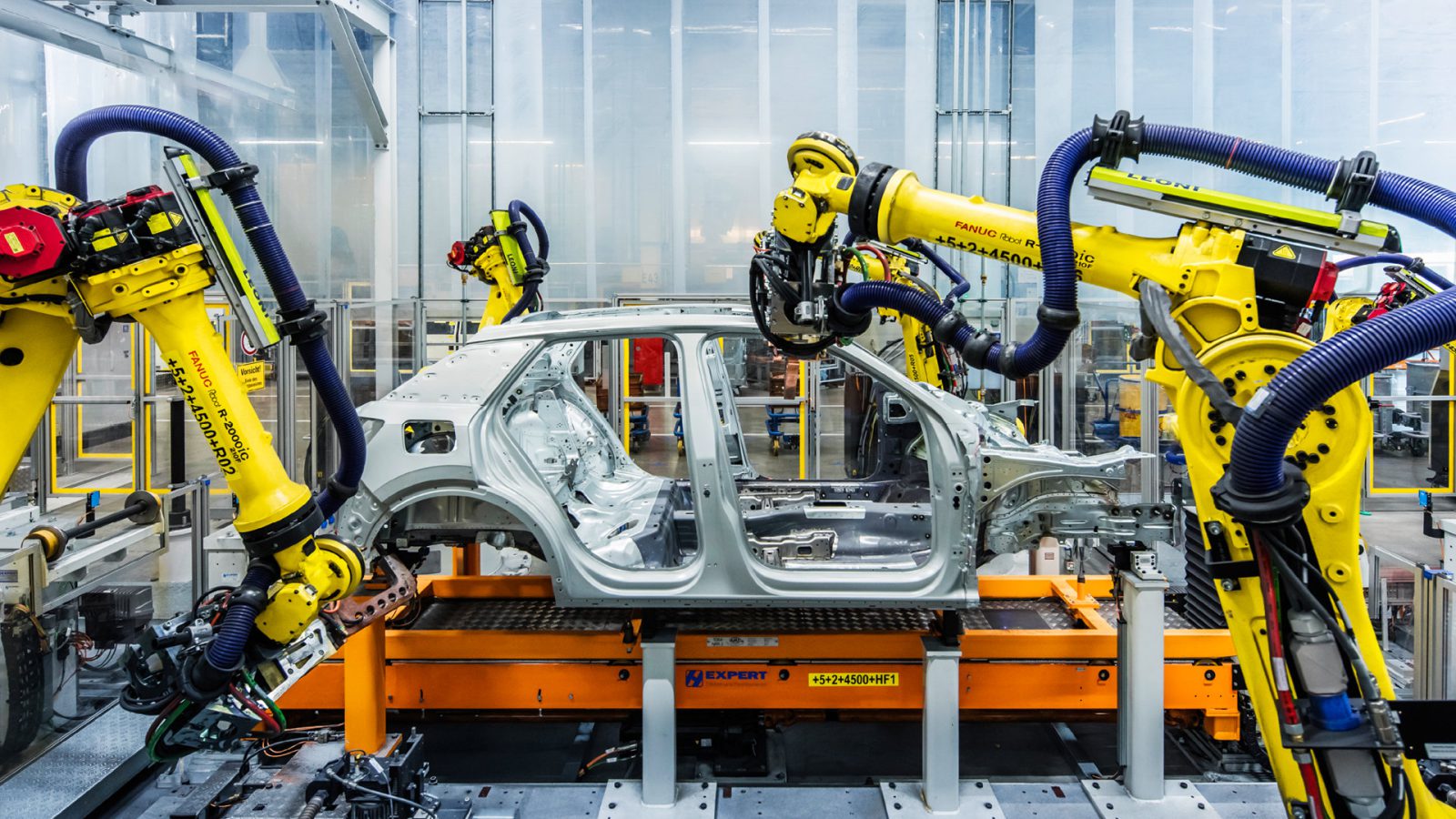

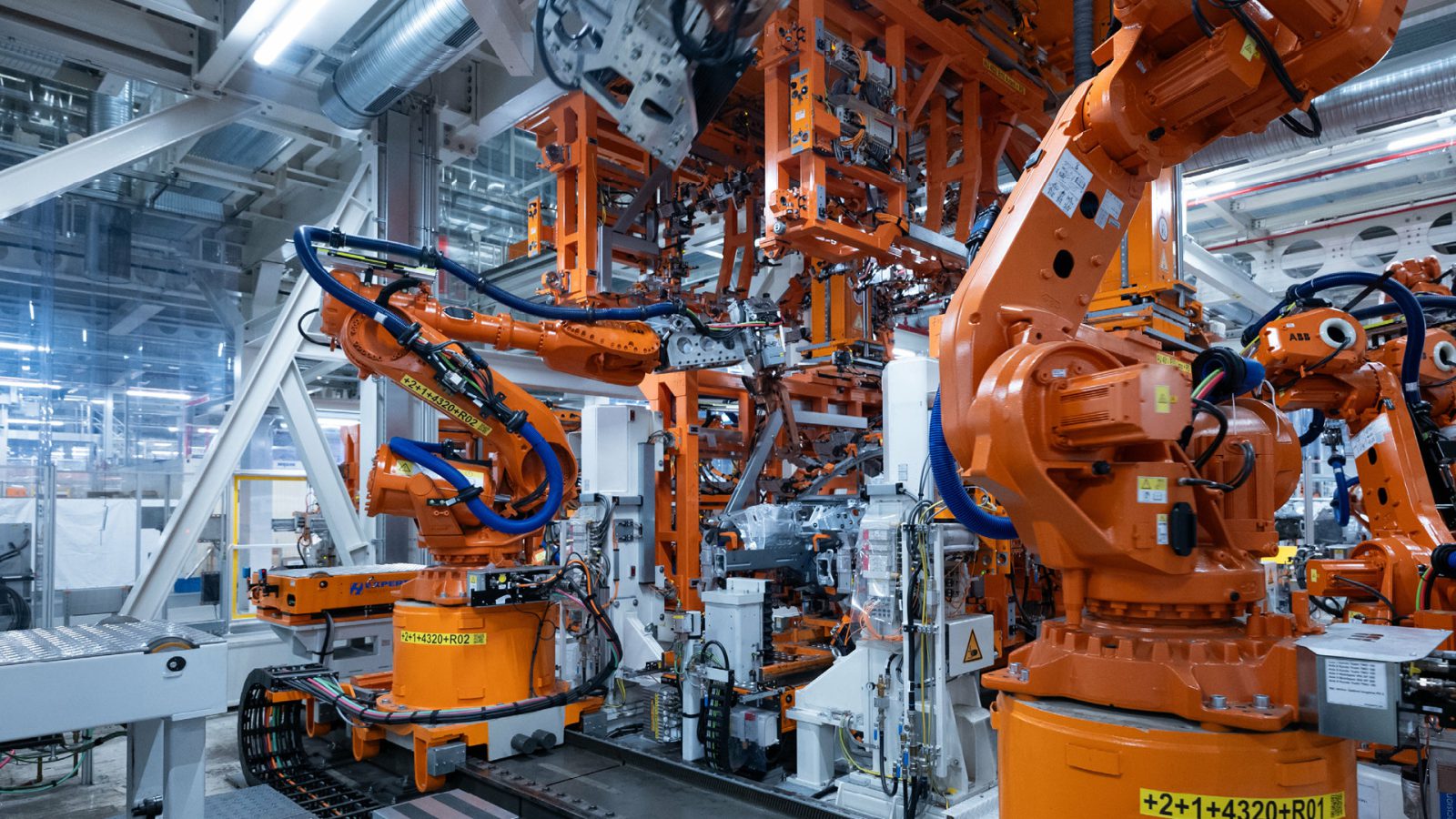

Development of customized automation solutions that can be seamlessly integrated into existing production infrastructures – including robot and PLC programming through our partner network.

Reconstruction and optimization of components and assemblies, even when CAD data is missing or outdated, to enable precise adjustments without production interruptions.

Competencies & Business Areas

With our historically grown and innovative engineering expertise, we take on the most demanding tasks across industries in three business Units. Both medium-sized companies and global corporations benefit from this – as we implement their individual requirements precisely and efficiently.

Industries

Our solutions are used in many industrial sectors – from agricultural engineering to aerospace. We ensure the specific optimization of production processes and the targeted introduction of automation. This way, we can gradually and sustainably strengthen the competitiveness of our customers.

Manufacturers of energy plants must supply durable, precisely manufactured components. Our range of services: Automation of manufacturing and testing processes, quality assurance, and production optimization for wind, water, gas, and conventional power plants.

Manufacturers of trucks and commercial vehicles face high demands in terms of efficiency and quality. Our range of services: automation of production and assembly lines, optimization of production processes, and integration of flexible solutions for high variant diversity.

Manufacturers of agricultural machinery and large components must ensure high robustness and adaptability. Our range of services: Automation of diverse manufacturing processes, quality assurance, and flexible production solutions to increase efficiency.

Joining technologies such as welding, bonding, and riveting are essential process steps in many industries. Our range of services: Development and implementation of automated joining solutions, process optimization, and ensuring reproducible quality.

The manufacture of aircraft requires the highest levels of precision, traceability, and safety standards. Our range of services: automated assembly and manufacturing processes, quality assurance, and integration of process-reliable production solutions.

Manufacturers of rail vehicles produce large components with high requirements in terms of structural strength and manufacturing quality. Our range of services: automation of manufacturing and assembly processes, material flow optimization, and quality assurance for large components.

Industrial companies with a broad product range require scalable automation solutions. Our range of services: process analysis, identification of automation potential, and customized solutions for increasing efficiency and quality.

Automotive engineering demands high development speed and vertical integration. Our range of services: Support for automated series production and optimization of assembly and testing processes. Defense (defense industry): The defense industry manufactures highly complex and safety-relevant systems. Our range of services: Automation of safety-critical manufacturing and assembly processes, quality assurance, and documentation.

The construction industry is increasingly benefiting from prefabricated modules and automated processes. Our range of services: automation in prefabrication, process optimization, and solutions to compensate for the shortage of skilled workers for sustainable construction production.

Manufacturers of large ship structures and systems face unique manufacturing challenges. Our range of services: Automation of large-scale manufacturing and assembly processes, specially tailored to the requirements of shipbuilding.

Electromobility requires new production processes and technologies for energy storage and drive systems. Our range of services: automation solutions for component manufacturing, production optimization, and scaling along the value chain.

The defense industry manufactures highly complex and safety-critical systems. Our range of services: Automation of safety-critical manufacturing and assembly processes, quality assurance, and documentation.

Through independent audits and certifications, we meet the highest standards in quality management.

Our expert team works with the most advanced software solutions and application technologies. This guarantees precise and reliable results at all times.

Success factor Network Organization

Interdisciplinary Teams

Our teams cover all areas of expertise: from design and simulation (e.g., CAD, CAE, robot simulation) to the development of tools (fixtures, gripping systems) and process automation. All project participants work together closely, which ensures short decision-making paths and smooth communication.

Strong Partner Networks

Through targeted cooperation with strategic network partners in research, development, and implementation, we create holistic solutions from a single source and cover a wide range of services: from early development phases to manufacturing and installation to the commissioning of tools and systems. For our customers this means: shorter project timelines, minimal interfaces, less coordination effort – and maximum efficiency in implementation.

Adaptable Organization

As a network organization, we can respond flexibly and quickly to new requirements – no matter how complex or dynamic a project is. We integrate new expertise in a targeted and needs-based manner without lengthy restructuring.

Customer Benefits

sbp offers solutions for a wide variety of industries, from mechanical engineering and electromobility to modular housing production. The concepts are flexible and scalable, so they can be adapted to different production requirements.

By using digital twins and precise 3D plant scans, potential planning risks are identified and minimized early on. This significantly increases planning reliability.

Thanks to data-based analyses and digital models, bottlenecks and optimization potentials can be quickly identified and implemented. This lowers production costs and increases productivity.

sbp develops solutions that meet current requirements while being flexible enough to adapt to future market changes. This ensures long-term investment security.

From semi- to fully automated solutions, sbp offers customized automation concepts that can be expanded depending on production volume and complexity.

Human-centered planning reduces physical strain and promotes long-term employee productivity.

With advanced automation solutions and continuous digitalization, sbp helps companies remain competitive in the long term.

Through close cooperation with technology partners and interdisciplinary teams, sbp can efficiently and flexibly implement even complex projects.