Classification and scope

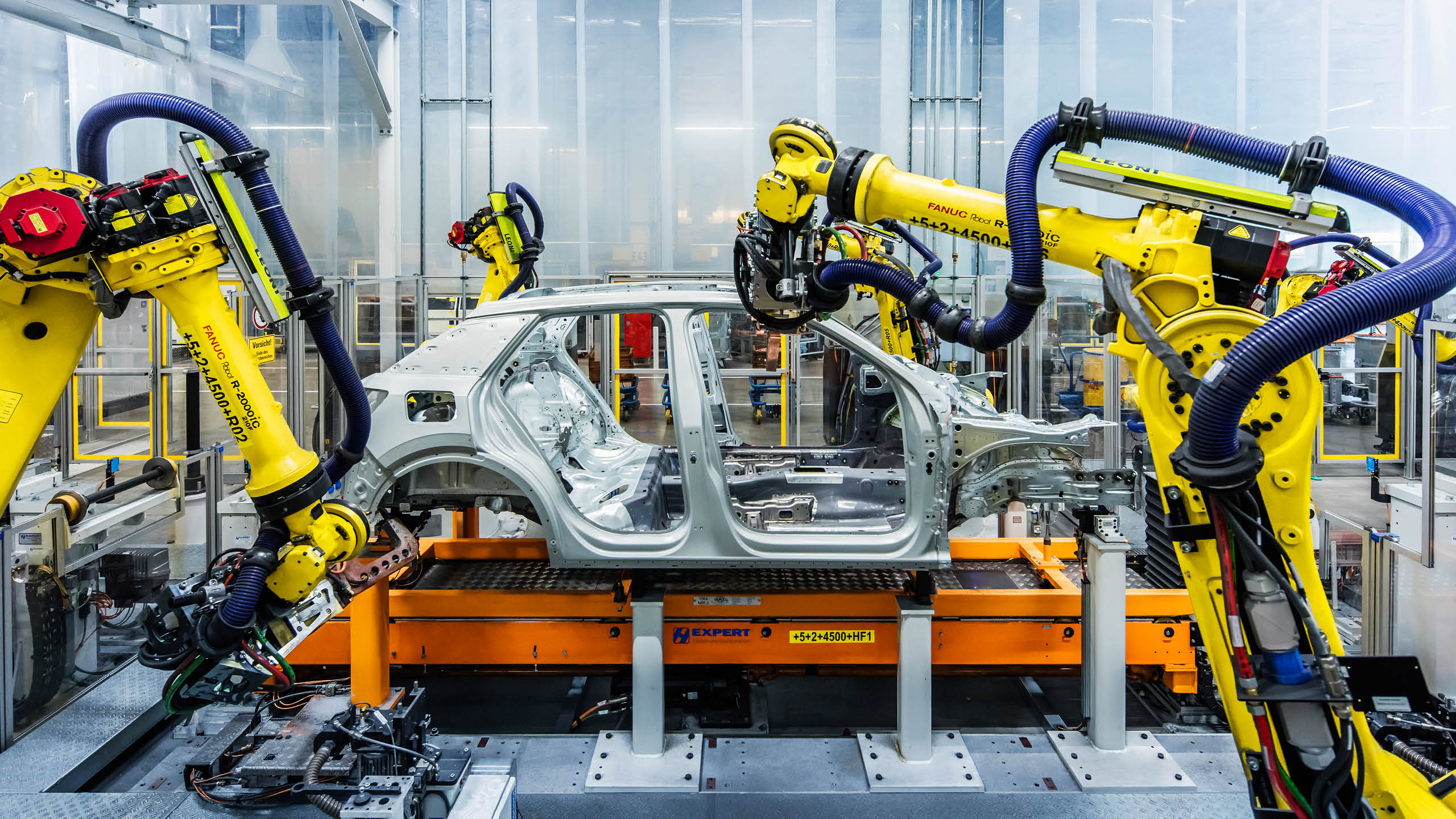

We developed a manufacturing concept for a German OEM in the luxury segment for the production of complete floor assemblies, including subassemblies. The high cycle time with an output of 3–5 vehicles per hour resulted in a correspondingly extensive workload per robot and worker.

Challenges

The central challenge was to combine different joining processes such as gluing, riveting, spot welding, and seam welding within a continuous process. Several vehicle types were to be flexibly mapped in a single line, and the system was to be optimized for the existing type at the same time. In addition, the project was in a very early phase of vehicle development with correspondingly dynamic product changes.

Our Solutions

We developed a hybrid plant concept that combines manual and automated process steps while ensuring a stable production flow. The entire plant design was supported by 3D simulation to ensure cycle times, process sequences, and accessibility at an early stage. At the same time, we took on the engineering project management, including technical documentation, and thus served the requirements of the various interest groups.

Additional information

Further information is available in person, subject to confidentiality agreements.