Initial situation & challenge

At a German car manufacturer’s plant in Brussels, an existing body shop was to continue being used for the series production of a new model. The aim was to manufacture two very different model variants—with partly conflicting requirements—on a shared line. The existing conveyor technology, space conditions, and plant structure were not originally designed for this.

Our solution

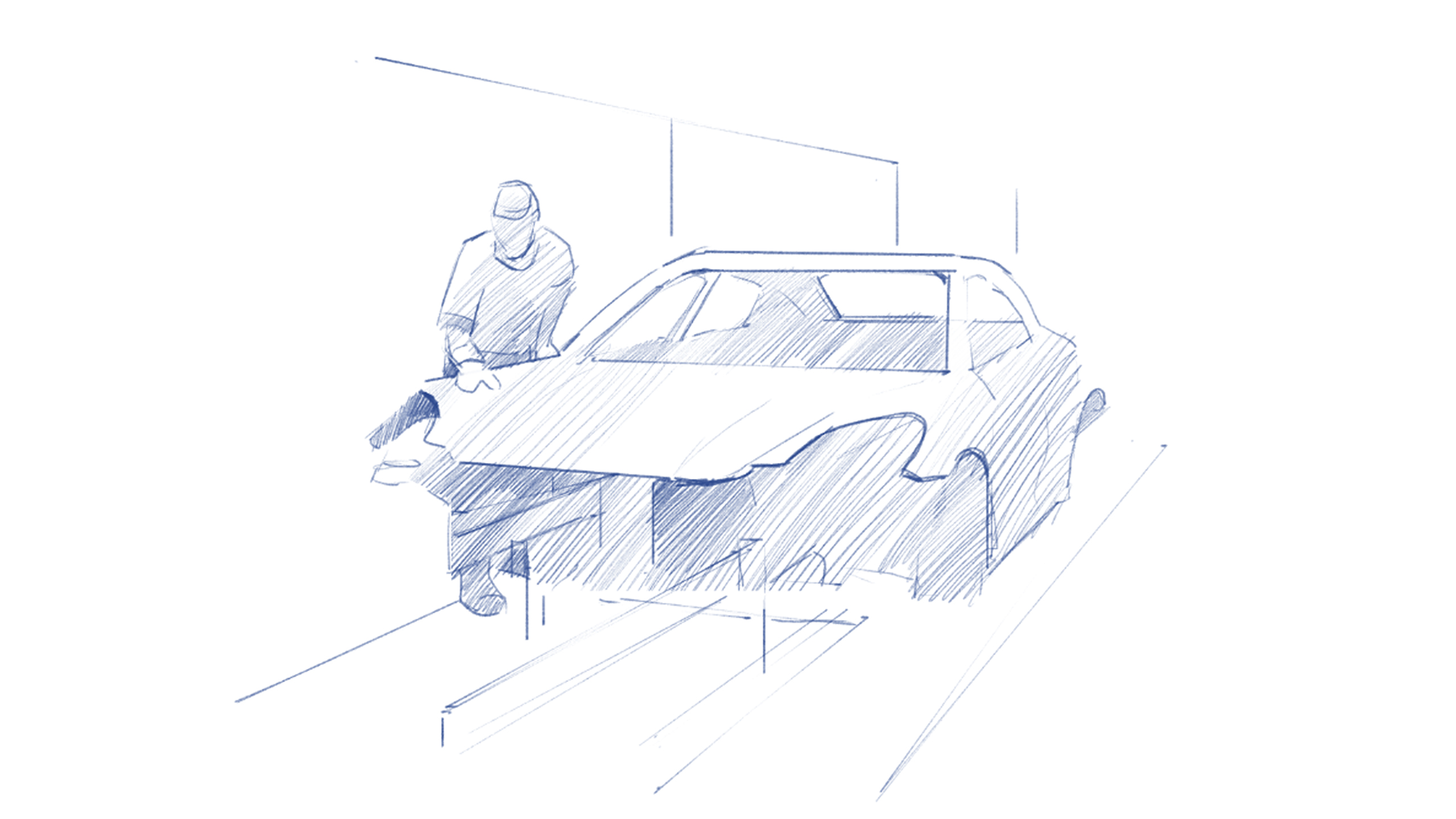

We developed a flexible plant concept that made it possible to efficiently process both small cars and SUVs on one line – internally referred to as the “combination of David and Goliath.” To achieve this, essential plant components were widened, converted, and adapted to new geometries. The conveyor technology was modified accordingly to move both vehicle types safely and on time through the plant – without compromising process reliability.

Result & customer benefit

The integration of both model variants into a common line reduced investment costs and saved valuable space in the plant. Despite considerable modifications, we were able to complete the conversion within a tight timeframe – while production continued and all quality requirements were met. With this project, we demonstrate that even existing structures can be successfully adapted to new challenges with clever planning and technical expertise.