Initial situation & challenge

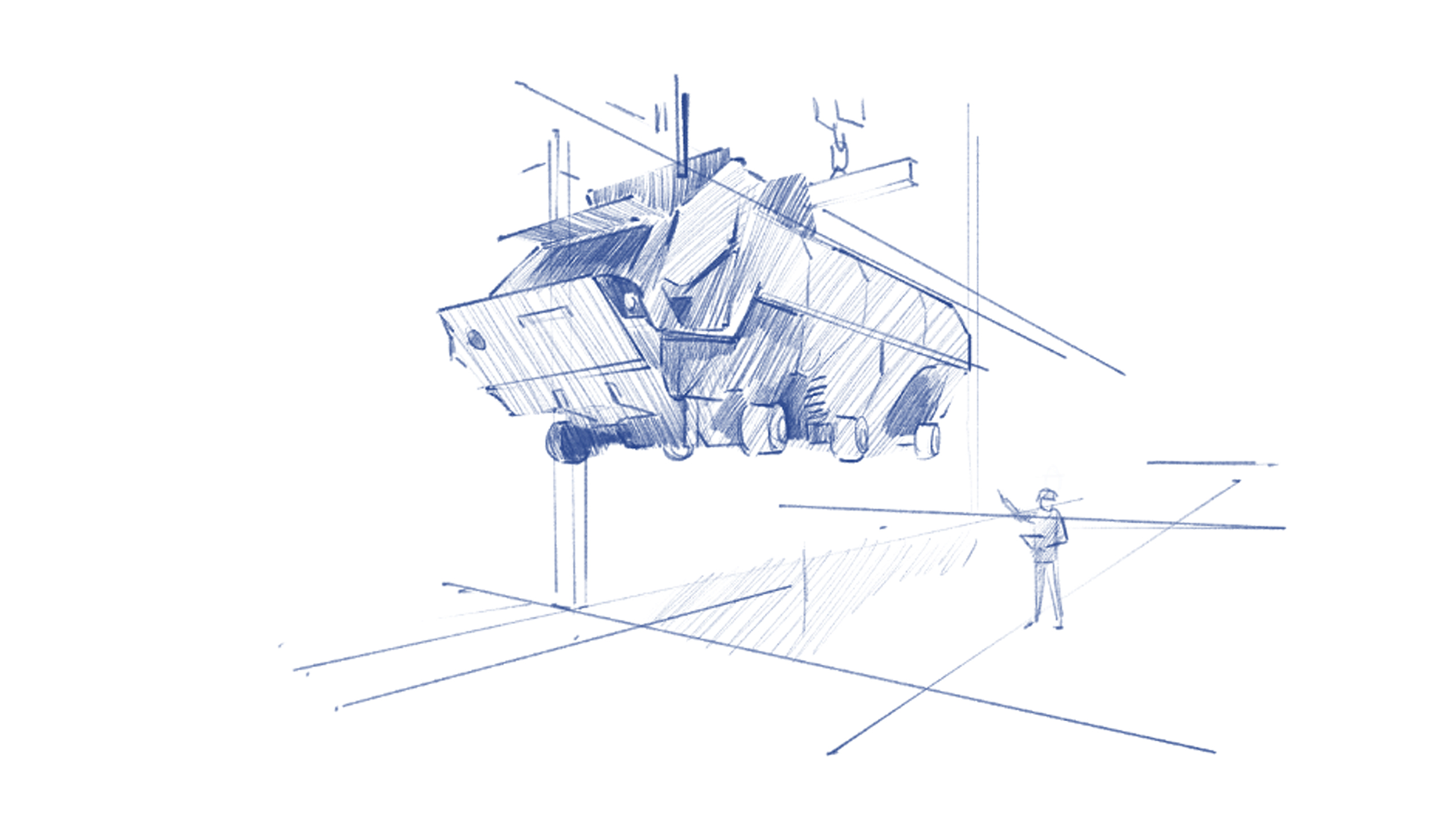

A leading German automotive manufacturer faced particular challenges in the welding production of armored vehicle components. The extremely heavy doors (over 200 kg) had to be repositioned precisely and without damage after painting—a process that had previously involved considerable effort. In addition, the production cell was to be set up in an existing hall whose floor load limits did not allow for conventional implementation.

Our Solution

We developed a customized solution for combining TV and TH manipulators, which allowed the massive doors to be handled safely and efficiently. At the same time, we worked closely with a structural engineering firm to design a floor concept with large steel plates that distributed the forces optimally and made it possible to install the system in the old building hall in the first place. The welding process on the “protection core” was optimally prepared through precise offline programming and virtual validation.

Result & customer benefit

The safe and damage-free installation of components weighing over 200 kg was reliably implemented – despite spatial restrictions. Through a combination of technical expertise, pragmatic engineering, and close cooperation with the customer and partners, we realized an extremely complex project with high efficiency and created a stable and future-proof manufacturing solution for the highly sensitive area of armored vehicle components.